What is OCC Waste Paper and Why Paper Mills Need Quality Suppliers

Old Corrugated Containers (OCC) remain the backbone of recycled paper production globally. Paper mills producing kraftliner, testliner, and corrugated medium rely on consistent OCC supply to maintain production schedules and product quality. Finding a reliable OCC supplier directly impacts your mill’s profitability, machine efficiency, and environmental compliance.

This comprehensive guide explains how to evaluate OCC suppliers, understand quality grades, and secure sustainable waste paper imports for your paper mill operations.

Understanding OCC Grades: What Paper Mills Should Know

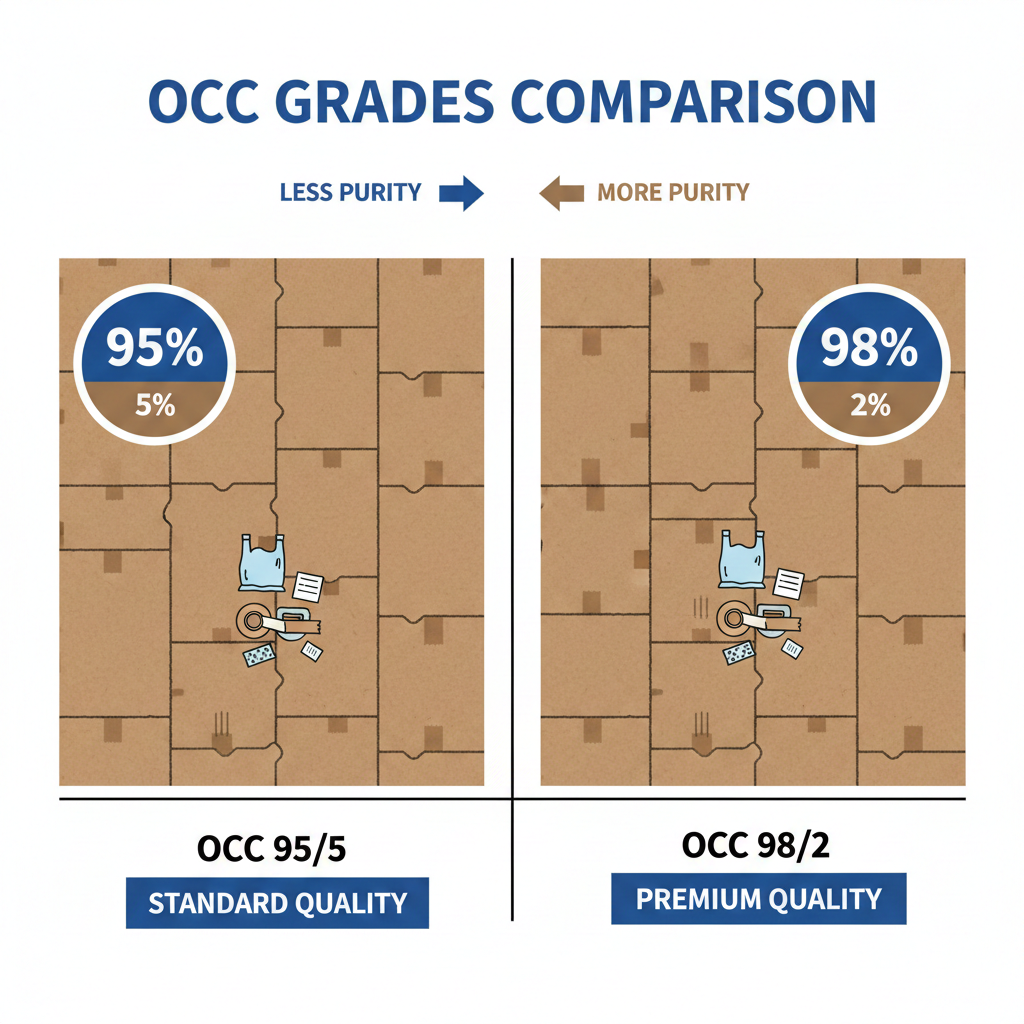

OCC Grade 11 (95/5 Standard)

The industry standard OCC Grade 11 contains minimum 95% corrugated containers with maximum 5% allowable outthrows. This grade works well for mills producing medium-grade packaging paper where cost efficiency matters more than premium fiber quality.

Typical applications:

- Corrugated medium production

- General packaging grades

- Cost-sensitive manufacturing runs

OCC Grade 11 (98/2 Premium)

Premium OCC 98/2 offers 98% corrugated content with only 2% maximum contamination. Mills producing high-strength packaging or export-grade paper prefer this specification for superior fiber yield and reduced screening losses.

Key advantages:

- 8-12% higher pulp yield compared to standard grades

- Reduced chemical consumption in pulping

- Lower equipment wear and maintenance costs

- Consistent burst factor and tensile strength

OCC Grade 12 (Double Sorted)

Double sorted OCC undergoes additional quality control, removing printed materials, wax-coated boxes, and foreign materials. This grade suits mills with strict contamination limits or those producing white-top kraftliner.

How to Evaluate an OCC Supplier: 7 Critical Factors

1. Quality Control and Inspection Process

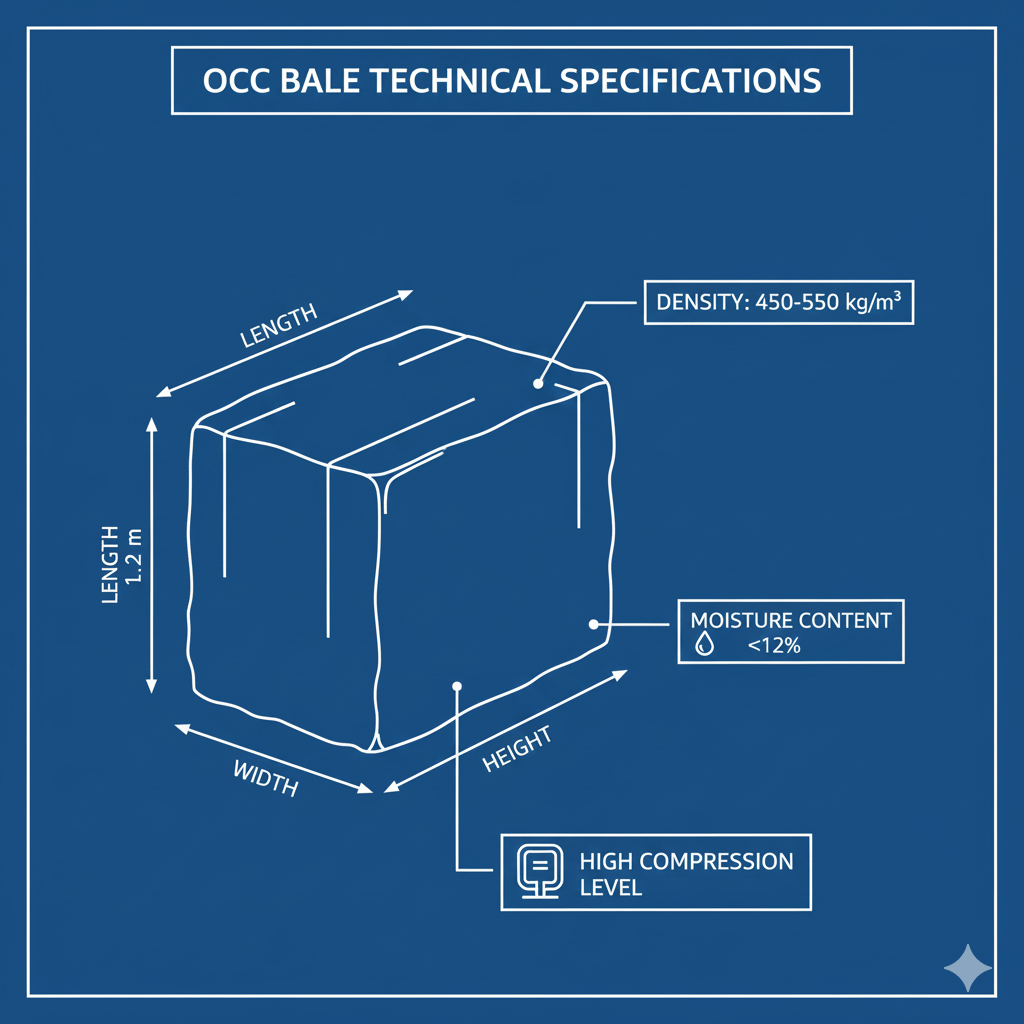

Professional waste paper importers conduct pre-shipment inspection covering moisture content, contamination levels, bale density, and prohibited materials. Ask potential suppliers about their QC protocols:

- Do they provide third-party inspection certificates?

- What’s their maximum moisture content guarantee (industry standard: 12-15%)?

- How do they handle contamination disputes?

- Can they provide sample bales before bulk orders?

2. Supply Consistency and Volume Capacity

Paper mills operate continuously, making supply reliability non-negotiable. Your OCC supplier should demonstrate:

- Minimum monthly supply capacity matching your consumption

- Multiple sourcing locations to prevent single-point failures

- Backup inventory during peak demand periods

- Track record of on-time deliveries over 12+ months

3. Pricing Structure and Payment Terms

Transparent pricing prevents unexpected costs. Evaluate these financial factors:

Price components to clarify:

- FOB (Free on Board) vs CNF (Cost and Freight) vs CIF (Cost, Insurance, Freight)

- Currency fluctuation handling

- Minimum order quantities

- Volume-based discount structures

Payment terms comparison:

- LC (Letter of Credit) at sight vs 30/60/90 days

- Advance payment discounts

- Payment against documents vs payment on arrival

4. Contamination Management

Contamination directly affects your production efficiency. Quality OCC suppliers implement strict protocols:

- Maximum prohibitives: <0.5% (plastics, metals, hazardous materials)

- Maximum outthrows: 2-5% depending on grade

- Moisture content: 12-15% maximum

- Bale density: 450-550 kg/m³ for container optimization

5. Export Documentation and Compliance

International waste paper trade requires proper documentation. Your waste paper importer should handle:

- AQSIQ registration (for China exports)

- ISRI specifications compliance

- Phytosanitary certificates

- Commercial invoices and packing lists

- Certificate of origin

- Quality inspection certificates

6. Logistics and Container Loading

Efficient logistics reduce landed costs. Evaluate supplier capabilities:

- Container stuffing expertise (typically 24-26 MT per 40ft HC)

- Port access and shipping line relationships

- Transit time optimization

- Container tracking and shipment visibility

7. Environmental and Social Certifications

Sustainable sourcing increasingly matters for brand reputation and regulatory compliance:

- FSC (Forest Stewardship Council) certification

- ISO 14001 environmental management

- Responsible sourcing documentation

- Local waste management compliance

Cost Analysis: How Quality OCC Impacts Paper Mill Profitability

Direct Cost Savings from Premium OCC

Using high-quality OCC 98/2 instead of standard 95/5 typically delivers:

Fiber yield improvement: 8-12% more usable fiber per ton

- Standard OCC 95/5: 82-85% fiber yield

- Premium OCC 98/2: 90-93% fiber yield

Chemical cost reduction: 10-15% lower consumption

- Reduced deinking chemicals needed

- Lower caustic soda requirements

- Decreased bleaching agent usage

Energy savings: 5-8% reduced power consumption

- Less screening and cleaning cycles

- Shorter pulping times

- Reduced waste handling

Calculating Your Break-Even Point

Example calculation for a 100 TPD paper mill:

Scenario A: Low-cost contaminated OCC at $180/MT

- Monthly consumption: 3,000 MT

- Fiber yield: 82%

- Usable fiber: 2,460 MT

- Contamination loss: 540 MT

- Effective cost per usable ton: $220

Scenario B: Premium OCC at $210/MT

- Monthly consumption: 3,000 MT

- Fiber yield: 91%

- Usable fiber: 2,730 MT

- Contamination loss: 270 MT

- Effective cost per usable ton: $231

While premium OCC costs $30/MT more, the actual cost difference per usable ton is only $11, offset by reduced chemical costs, lower downtime, and better finished paper quality.

Common OCC Sourcing Mistakes Paper Mills Make

Mistake 1: Choosing Suppliers Based Only on Price

The cheapest OCC often carries hidden costs through contamination, moisture manipulation, or inconsistent quality. Mills focused solely on per-ton pricing frequently experience:

- 15-25% higher screening rejects

- Increased machine downtime for cleaning

- Quality complaints from finished paper customers

- Unpredictable production planning

Mistake 2: Not Verifying Supplier Claims

Some exporters misrepresent their capabilities or quality standards. Always verify:

- Request references from current paper mill customers

- Conduct facility audits for high-volume contracts

- Start with trial shipments before bulk commitments

- Check business registration and export licenses

Mistake 3: Ignoring Seasonal Supply Variations

OCC availability fluctuates with retail cycles, e-commerce activity, and regional collection systems. Smart mills:

- Negotiate contracts covering low-availability periods

- Build 2-3 weeks buffer inventory during peak seasons

- Work with suppliers having diverse geographic sources

- Plan maintenance shutdowns during supply constraints

Mistake 4: Inadequate Contract Specifications

Vague agreements lead to disputes. Your OCC purchase contract should specify:

- Exact grade definitions with visual references

- Moisture content testing methodology

- Contamination limits and classification

- Dispute resolution procedures

- Quality claims timeline and compensation

Regional OCC Supply Markets: Where to Source

North American OCC

Characteristics:

- Generally high quality due to strict sorting

- Premium pricing reflects quality

- Stable year-round availability

- Strong regulatory compliance

Best for: Mills producing high-grade kraftliner or export packaging

European OCC

Characteristics:

- Excellent sorting infrastructure

- Mixed grade availability (79-83% OCC mixes common)

- Competitive pricing on mixed grades

- Strong environmental certifications

Best for: Mills with flexible input specifications accepting mixed grades

Middle East OCC

Characteristics:

- Growing supply from GCC countries

- Variable quality requires inspection

- Competitive pricing

- Increasing collection infrastructure

Best for: Regional mills seeking short shipping distances

Asian OCC

Characteristics:

- Japan produces high-quality OCC from organized collection

- Southeast Asia offers growing supply with variable quality

- Competitive pricing on standard grades

- Mixed regulatory environments

Best for: Mills balancing quality and cost within Asia-Pacific region

How to Start Working with a New OCC Supplier

Phase 1: Initial Qualification (Week 1-2)

- Request company profile with export history

- Ask for current customer references in paper industry

- Review quality control procedures documentation

- Confirm minimum and maximum supply capacity

- Discuss pricing structure and payment terms

Phase 2: Trial Shipment (Week 3-6)

- Order 1-2 containers of specified grade

- Conduct pre-shipment inspection (third-party recommended)

- Track shipment and document arrival condition

- Run production trials measuring:

- Actual fiber yield vs claimed

- Contamination levels

- Moisture content

- Screening rejects percentage

- Finished paper quality parameters

Phase 3: Performance Evaluation (Week 7-8)

- Compare trial results against supplier claims

- Calculate actual landed cost per usable ton

- Evaluate documentation accuracy and completeness

- Assess supplier communication and responsiveness

- Make go/no-go decision for ongoing partnership

Phase 4: Contract Negotiation (Week 9-12)

- Negotiate volume commitments and pricing

- Establish quality standards and testing methods

- Define shipment schedules and logistics

- Agree on payment terms and currency

- Create dispute resolution procedures

Technology and Innovation in OCC Supply

Blockchain for Supply Chain Transparency

Progressive OCC suppliers now offer blockchain-verified tracking showing:

- Collection point documentation

- Quality inspection timestamps

- Chain of custody records

- Carbon footprint calculation

- Certification verification

AI-Powered Quality Prediction

Some waste paper importers use computer vision and AI to:

- Pre-grade material before baling

- Predict moisture content variations

- Identify contamination before shipment

- Optimize bale loading patterns

Digital Trading Platforms

Online marketplaces connect paper mills directly with OCC suppliers offering:

- Real-time pricing transparency

- Digital quality certificates

- Automated documentation

- Shipment tracking integration

Environmental Benefits of Working with Responsible OCC Suppliers

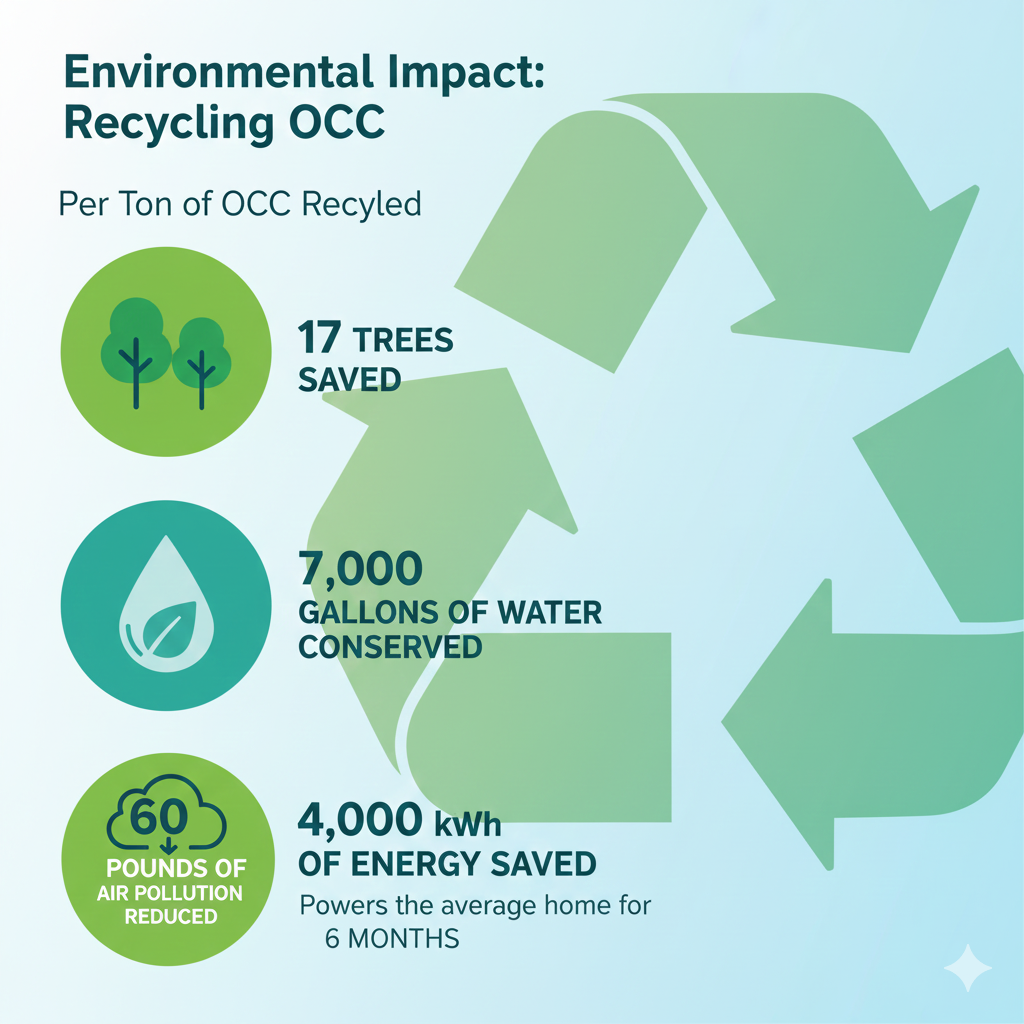

Carbon Footprint Reduction

Using recycled OCC instead of virgin pulp saves approximately:

- 17 trees per ton of paper produced

- 7,000 gallons of water

- 4,000 kWh of energy

- 60 pounds of air pollutants

Circular Economy Contribution

Responsible OCC suppliers support circular economy principles through:

- Diverting waste from landfills

- Reducing virgin forest harvesting

- Creating green jobs in collection and sorting

- Supporting sustainable packaging systems

Meeting Sustainability Targets

Paper mills increasingly face pressure to document sustainable sourcing. Working with certified OCC suppliers helps demonstrate:

- Percentage of recycled content in products

- Supply chain transparency

- Environmental management compliance

- Corporate social responsibility goals

Questions to Ask Potential OCC Suppliers

Before finalizing your OCC supplier partnership, get clear answers to:

- What is your average monthly export volume? (Indicates capacity and stability)

- Can you provide 3 references from paper mills you currently supply? (Verifies track record)

- What is your standard moisture content, and how do you test it? (Prevents weight disputes)

- Do you offer pre-shipment inspection by third parties? (Shows quality confidence)

- What is your typical contamination rate for the grade we need? (Sets realistic expectations)

- How do you handle quality claims and compensation? (Reveals dispute resolution)

- What are your minimum order quantities and lead times? (Ensures supply compatibility)

- Which ports do you ship from, and what are typical transit times? (Affects logistics planning)

- Do you hold relevant environmental certifications? (Important for sustainability reporting)

- What payment terms do you offer, and do you work with letters of credit? (Clarifies financial arrangements)

Conclusion: Building Long-Term OCC Supply Partnerships

Selecting the right OCC supplier involves more than comparing prices per ton. Paper mills that invest time in thorough supplier evaluation, start with trial shipments, and build relationships with reliable waste paper importers achieve:

- 15-20% lower effective raw material costs

- Reduced production variability and downtime

- Better finished paper quality and customer satisfaction

- Predictable supply for production planning

- Stronger sustainability credentials

The global OCC market continues evolving with increased quality expectations, technological innovation, and environmental accountability. Mills that partner with forward-thinking OCC suppliers position themselves for long-term competitive advantage in the recycled paper industry.

Ready to Source Quality OCC for Your Paper Mill?

Contact us to discuss your specific requirements, request sample shipments, or schedule a consultation with our waste paper sourcing specialists. Matvex supply consistent, quality-verified OCC to paper mills across India, with flexible terms and competitive pricing backed by 20+ years of industry experience.