Introduction: Why OCC Scrap Paper Grades Matter

OCC (Old Corrugated Containers) scrap paper is one of the most widely used raw materials in the kraft paper and duplex board industry. However, not all OCC scrap paper is the same.

Understanding OCC scrap paper grades—OCC 11, OCC 12, and Mixed OCC—is critical for paper mills to control:

- Pulp quality

- Strength of finished paper

- Machine efficiency

- Overall production cost

In this blog, we break down each OCC grade, its specifications, applications, and which type of mill it suits best.

What Is OCC Scrap Paper?

OCC scrap paper refers to used corrugated cartons and boxes collected from commercial, industrial, and retail sources. These cartons are recycled and converted into pulp, mainly for:

- Kraft paper

- Test liner

- Corrugated boards

- Packaging paper

OCC is preferred due to its high fiber strength, availability, and cost efficiency.

OCC 11 Scrap Paper – Definition & Specifications

✅ What Is OCC 11?

OCC 11 is a high-quality grade of Old Corrugated Containers, consisting primarily of clean, dry, and sorted corrugated cartons with minimal contamination.

It is one of the most demanded OCC scrap paper grades globally, especially for mills producing premium kraft paper.OCC & Waste Paper

📌 OCC 11 Specifications (Typical)

- Clean corrugated boxes only

- Minimal waxed cartons

- Low moisture content

- Very low plastic, tape, or metal contamination

- Uniform bale quality

🏭 Where OCC 11 Is Used

- High GSM kraft paper manufacturing

- Premium corrugated boxes

- Export-grade packaging paper

- Mills requiring consistent strength and burst factor

⭐ Advantages of OCC 11

- High fiber yield

- Better pulp strength

- Lower rejection during pulping

- Consistent machine performance

OCC 12 Scrap Paper – Definition & Specifications

✅ What Is OCC 12?

OCC 12 is also Old Corrugated Containers but allows slightly higher tolerance for impurities compared to OCC 11. It is commonly used where cost optimization is more important than ultra-high quality.

📌 OCC 12 Specifications (Typical)

- Corrugated cartons with moderate sorting

- Slightly higher moisture allowed

- Minor presence of tapes, labels, or mixed board

- Still suitable for recycling without major issues

🏭 Where OCC 12 Is Used

- Medium GSM kraft paper

- Duplex board back layers

- Test liner paper

- Mills balancing cost and performance

⭐ Advantages of OCC 12

- More economical than OCC 11

- Good fiber strength for most applications

- Widely available in domestic and imported markets

Mixed OCC Scrap Paper – When and Why It’s Used

✅ What Is Mixed OCC?

Mixed OCC waste paper contains corrugated cartons mixed with other kraft papers, liners, or minor non-corrugated material. Sorting quality is lower compared to OCC 11 and OCC 12.

📌 Mixed OCC Characteristics

- Mixed corrugated and kraft paper

- Higher contamination risk

- Variable bale consistency

- Lower fiber strength compared to OCC 11/12

🏭 Where Mixed OCC Is Used

- Low GSM kraft paper

- Inner layers of corrugated boards

- Mills with strong screening & cleaning systems

- Cost-sensitive production lines

⚠️ Things to Watch in Mixed OCC

- Moisture levels

- Wax-coated cartons

- Excess plastic and straps

- Uneven bale weights

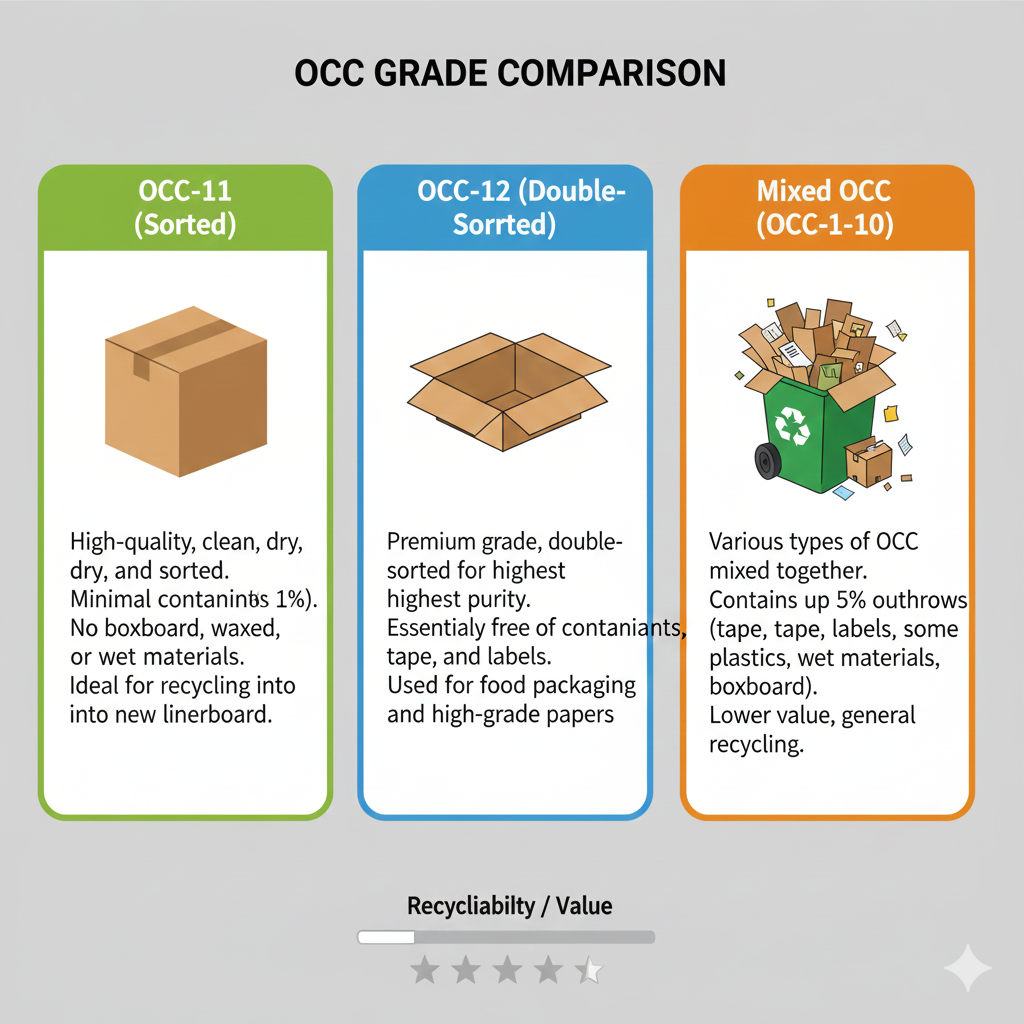

OCC Scrap Paper Grades Comparison Table

| Parameter | OCC 11 | OCC 12 | Mixed OCC |

|---|---|---|---|

| Quality Level | High | Medium | Low to Medium |

| Sorting Level | Highly sorted | Moderately sorted | Poorly sorted |

| Contamination | Very Low | Low | Medium to High |

| Moisture Tolerance | Low | Moderate | Higher |

| Fiber Strength | Excellent | Good | Average |

| Cost | Highest | Medium | Lowest |

| Best For | Premium kraft paper | Standard kraft & duplex | Low-cost production |

Which OCC Grade Suits Which Paper Mill?

🏭 Choose OCC 11 if:

- You manufacture high-strength kraft paper

- Export packaging quality matters

- You want low rejection and consistent output

🏭 Choose OCC 12 if:

- You produce standard kraft or duplex paper

- You want a balance of cost and quality

- Your machines handle minor impurities well

🏭 Choose Mixed OCC if:

- Cost control is your top priority

- Your mill has advanced screening systems

- You manufacture low to medium GSM paper

Final Thoughts

Selecting the right OCC scrap paper grade directly impacts paper quality, production efficiency, and profitability. While OCC 11 delivers the best performance, OCC 12 and Mixed OCC offer practical alternatives based on budget and application.

Understanding these differences helps mills make informed procurement decisions and avoid quality surprises.

Looking for reliable sourcing of OCC 11, OCC 12, or Mixed OCC scrap paper with clear specifications and consistent quality?

Contact MATVEX Trade for transparent grading, dependable supply, and mill-focused solutions.